VH (Variable Height) - Horizontal beam with camera can be fixed at any desired level. Designed to perform alignment on Scissor lift, Four Post Lift and Pit .

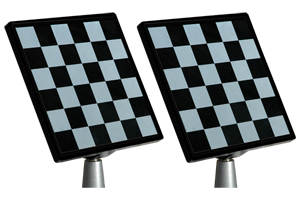

- Vision based 3D Imaging technology using 2 High Performance SI (Scientific Image) Camera

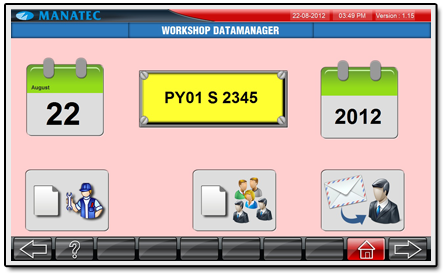

- Simultaneous Front and Rear wheel alignment (4×4)

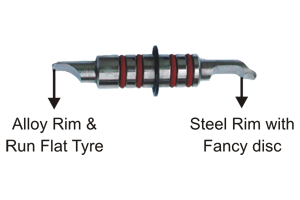

- Push Pull Runout /Setback / Thrust angle compensation

- Lift level compensation at adjustment level

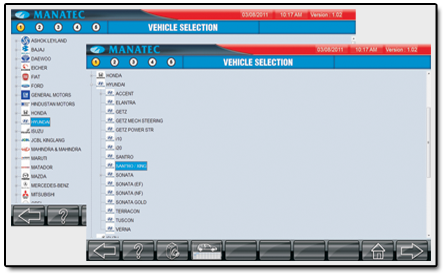

- Unlimited memory for vehicle specifications

- Option for selection of vehicle specification during alignment

- Power failure data protection

- Automatic tracking of Left & Right turns for Caster/Kingpin measurements

- Adjustment of Camber in wheel Jacked-up position & Toe curve measurement

- Rear Setback & Track width difference,

- Toe adjustment in single Tie rod vehicle, Vehicle geometry measurements

- Effortless Toe (Easy Toe) adjustment program

- Camber measurement at Zero Toe

- Drag link adjustment

- Toe out on Turns & Lock angle measurements

- Animated pictorial display of angles during alignment

- Zoom in option for live parameters

- Two Color Bar display for adjustment of all angles

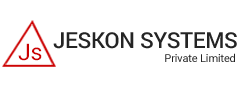

- Quick Wheel Alignment program by user defined

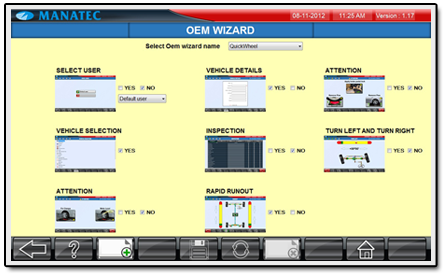

- Data Manager Software for storing alignment results

- Customer Address in printout & customer data edit option

- 3-D Pictorial & Two color text printout

- Multi-lingual program & Voice prompt

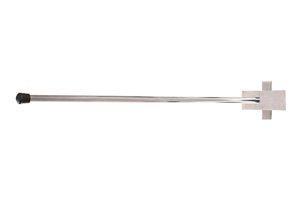

- Two wheel Alignment program by fixing only front two target plates