- For Large Open Channels and Pipes (6 ft / 2 m or larger)

- Includes 3 Velocity Sensors for Average Velocity measurement

- Measures Forward and Reverse Flow

- 3 Isolated 4-20mA Outputs(Flow, Level and Velocity)

- Totalizer and 2 Control Relays

- Simple 5-key Calibration

- Optional built-in 2-million point Data Logger and Software with USB output to Flash Drives

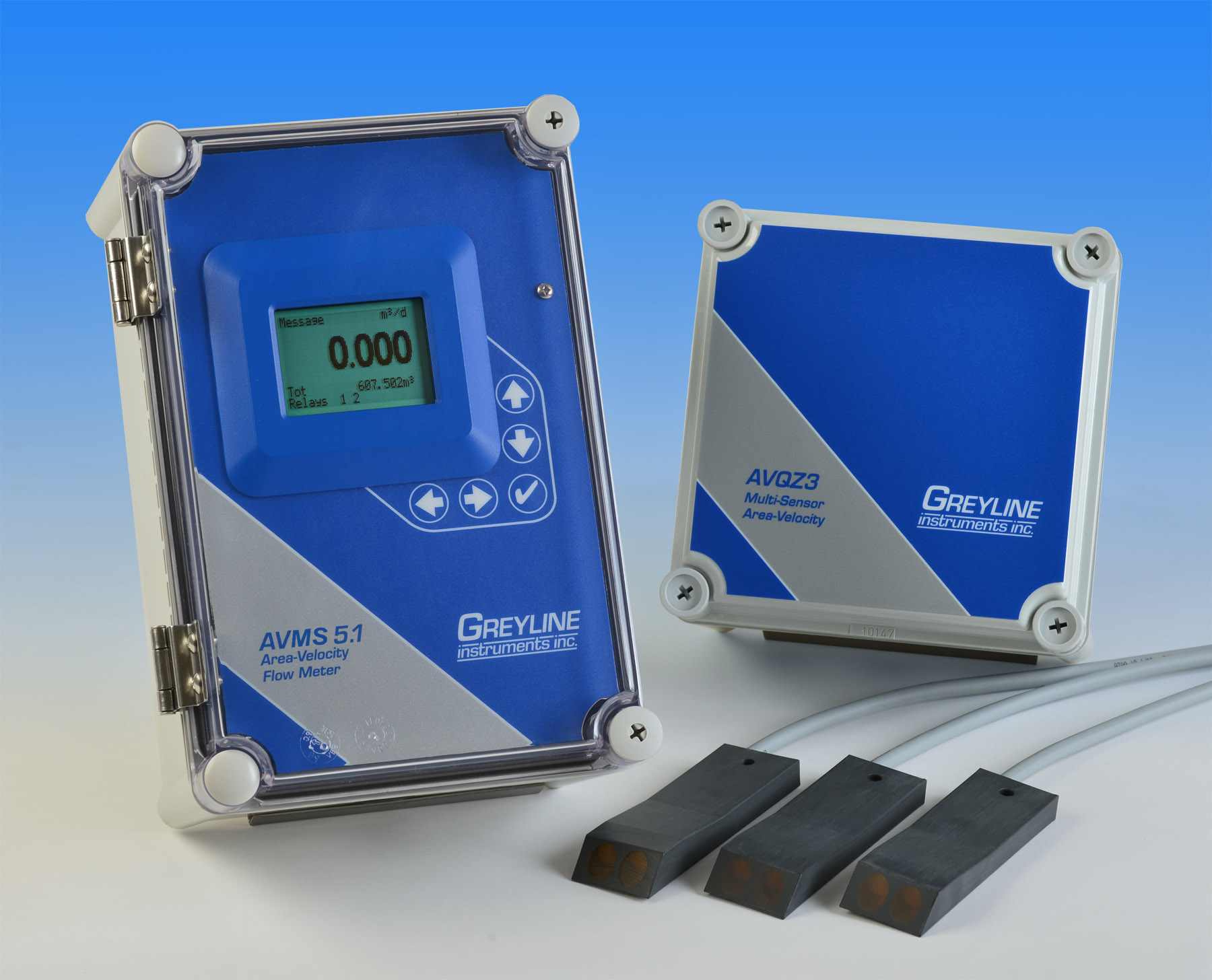

AVMS 5.1 Multi-Sensor Area-Velocity Flow Monitor

Measures Velocity + Level to Monitor Flow with Multiple Ultrasonic Sensors

Monitor flow through large open channels, partially full sewer pipes and surcharged pipes without a flume or weir. Designed for municipal stormwater, stream flow, irrigation water, raw sewage, sluiceways, water intake channels, cooling water discharges and industrial effluent.

The AVMS 5.1 uses three submerged ultrasonic sensors to continuously measure both Velocity and Level in the channel. It is recommended for large channels or applications where velocity will vary across the width of the channel.

The sensors resist fouling, corrosion and abrasion. The flowmeter can be configured with three standard submerged velocity-level sensors, or with three submerged velocity plus a separate non-contacting ultrasonic level sensor.

How it Works

The AVMS 5.1 Area-Velocity Flow Meter measures level and average velocity from multiple sensors to calculate flow in open channels or pipes. The system includes the AVMS 5.1 flowmeter with interconnect cable to a multi-sensor enclosure plus three submerged ultrasonic sensors.

The ultrasonic velocity sensors mount in the channel in positions where they will be submerged. Stainless steel mounting brackets are included. The sensors are completely sealed with no orifices or ports. Level is measured by connecting the built-in level sensor from any one of the three velocity sensors, or with an optional non-contacting ultrasonic level sensor.

Channels of any shape can be monitored. Forward and reverse flow can be measured and totalized. View flow rate and total flow on the large backlit LCD display and connect to external devices with three 4-20mA outputs and two control relays. The AVMS 5.1 measures flow velocity from 0.1 to 20 ft/sec (0.03 to 6.2 m/sec) and reverse flow up to 5 ft/sec (1.5 m/sec).

Contact Greyline Instruments for specific recommendations in your application.

SCOPE: This specification covers an ultrasonic, multi-sensor area-velocity flow monitor as manufactured by Greyline Instruments, Massena, New York / Long Sault, Ontario. The instrument shall provide for indicating, transmitting and totalizing of the flow rate through partially filled or surcharged round pipes and rectangular, trapezoidal, egg or irregular shaped open channels.

A. GENERAL

- Flow Monitor to consist of three submersible ultrasonic sensors, connecting cable, and remote enclosures with indicating, transmitting and controlling electronics. The system shall have no moving parts.

- Level measurement accuracy shall be ±0.25% of Range. Velocity measurement accuracy shall be ±2% of average reading from multiple sensors.

B. SENSING ELEMENTS

- Three ultrasonic sensors shall be rated IP68 for continuous submersion in liquids.

- Using the Doppler principle, three sensors shall measure fluid velocities from 0.1 to 20 ft/sec (0.03 to 6.2 m/sec) and reverse flow to -5 ft/sec (-1.5 m/sec).

- Readings from three separately mounted velocity sensors shall be continuously averaged by the instrument.

- Zero readings shall be automatically factored out if one or more velocity sensors are not submerged or become covered in sediment.

- Using ultrasonic echo-ranging principle, one of the submerged sensors shall measure liquid level from 1" to 15 ft. (25.4 mm to 4.57 m). Minimum level shall not be greater than 1" (25.4 mm). Level sensing circuitry shall include a temperature sensor for automatic temperature compensation.

- Sensors shall be constructed of PVC and epoxy resin.

- Sensor operating temperature shall be 5°F to 150°F (-15°C to 65°C).

- Shall include manufacturer's recommended stainless steel sensor mounting brackets.

C. SENSOR CONNECTING CABLE

- Provide minimum length 25 ft (7.6 m) tri-coaxial cable with potted bond to each Sensor head. Sensor cable shall be waterproof and electrically shielded. Exposed material shall be polyurethane only.

- Extended sensor cable shall be shielded tri-coaxial to a maximum length of 500 ft (152m). Cable shall be spliced with screw terminal connections in manufacturer’s recommended IP66 Junction Box.

D. TRANSMITTER

- The transmitter shall provide for field calibration to round pipes and open channels of any shape.

- Calibration shall be via built-in 5-key calibration system with menu selection of parameters with English, French or Spanish language selection.

- Calibration data shall be password protected and permanently stored through power interruptions for a minimum of 12 months.

- Field calibration shall allow selection and automatic conversion of measurement units, measurement span, high/low flow alarm relay and flow proportional relay pulse rates.

- Transmitter shall permit field programmable damping to smooth output in turbulent flow conditions.

- Transmitter operating temperature shall be from -5° to 140°F (-20° to 60°C). Transmitter shall contain a thermostat-controlled enclosure heater for condensation protection below 30°F (-1°C).

- Transmitter shall have three isolated 4-20mA outputs rated for 1000 ohm maximum load with menu-selectable 0-5VDC alternative. Outputs shall be configured to transmit level, velocity and flow.

- Provide two relay contacts rated 5 amp SPDT programmable for flow proportionate pulse to a remote totalizer or sampler, high-low flow, velocity and/or level alarm, echo loss alarm.

- Provide a white, backlit matrix LCD display indicating flow rate, level, velocity, relay states and 14-digit totalizer in user-selected engineering units.

- Transmitter display indicating flow rate, units of calibration, totalizer and relay states shall be visible without opening cover.

- Transmitter shall be housed in a wall-mount, watertight NEMA4X (IP66) enclosure with hinged, clear cover. Mounting hardware shall be included.

- Transmitter electronics shall be surge protected on AC power input, sensor and 4-20mA outputs.

- Transmitter power input shall be 100-240VAC 50-60Hz with power consumption of 5.28 Watts or less.

- The transmitter shall permit plug-in field installation and auto-detection of optional accessories including data logger and additional control relays.

E. MULTI-SENSOR TRANSMITTER

- The flowmeter shall include a digitally controlled remote transmitter-receiver module with terminal connections for velocity and level sensors.

- The sensor transmitter electronics shall be housed in a NEMA4X (IP66) polycarbonate enclosure.

- Sensor transmitter electronics shall be powered by connection to the flow meter transmitter.

- Enclosure interconnect cable shall be 100 ft (30 m) length heavy-duty Cat 5.

F. OPTIONAL FEATURES FOR INSERTION AS REQUIRED

Sensors

- Have a separate non-contacting ultrasonic level sensor mounted above the liquid. The non-contacting level sensor shall be rated for measurement range from 8" to 15 ft. (203.2 mm to 4.5 m) and shall include integral temperature compensation.

- Sensor cables shall be 50 ft. (15 m) continuous length with potted bond to the Sensor head.

- Sensor cables shall be 100 ft. (30 m) continuous length with potted bond to the Sensor head.

- Multi-Sensor Transmitter interconnect cable shall be 328 ft (100 m) length heavy-duty Cat 5.

- Separate length extended sensor cable shall be shielded tri-coaxial to a total maximum length of 500 ft (152m). Cable shall be spliced with screw terminal connections in manufacturers recommended IP66 Junction Box.

Electronics

- Have a built-in Have a built-in 2 million point Data Logger with USB output to flash drives or mass storage devices. Data logger shall support time and date-stamped logging and generate formatted flow reports including total, average, minimum, maximum and times of occurrence. Include Windows software for data log graphing and export.

- Have a thermostat controlled enclosure heater for Transmitter operation at temperatures below freezing.

- Have manufacturer's recommended enclosure sunscreen to permit Electronics enclosure mounting in direct sunlight.

- Transmitter power input shall be 9-32VDC with minimum power consumption of 6.5 W max.

G. MANUFACTURER